Lot of friends here may have experience for DIY yourselves ultralight outdoor gears. So you are come the right place here. Okay let’s talk about the questions.

There are a lot of fabrics used for outdoor ultralight tent, tarp, hammock and so on. How do we choose the best one for our DIY gears?

Usually it’s nylon material and polyester material with different woven like plain, ripstop, twill. And also different coating on the ultralight fabric, PU, silicone or double side with silicone/Pu coating. I will explain to you about the functions of them.

First, the material of basic fabric is important. Nylon is a popular material due to its high strength, excellent durability and ability to withstand pressure, is the preferred option for outdoor brand’s in the market. However, nylon also has its drawbacks. Due to its high elongation rate, the fabric may deform to some extent under the influence of damp weather, such as rainy days, and also effected by air pressure. If you observe carefully, you might see that the pressure of accumulated water on the tent has caused a shift in the position of your tent relative to the support poles. Just like the clothes that have been stretched out no longer fit body. Once the tent has dried, the fabric will shrink and revert to its original condition. This is really FK, right?

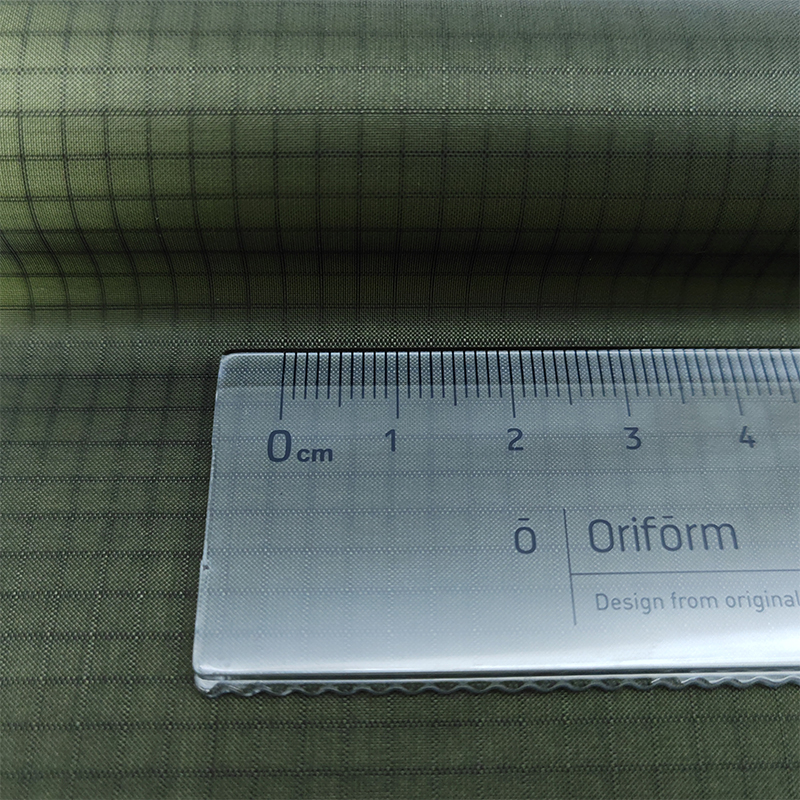

So there are handsome guys and beautiful girls may asked why don’t we use polyester material for tent?Yeah, Polyester actually is a cheaper option for outdoor gears. Becuase it strength and abrasion resistance is harder than nylon. But it still is a good choice for tent , tarp because it elongation is poor so it will not shift like nylon. If your purchase quantity is large and also budget is good , then you can customized super high strength polyester yarn to weave the fabric , which will sovle the problems. Pls notice that moq of supplier may very large. Ripstop grid is better than plain and twill.

I have come to realize that my previous explanation may have been overly detailed, possibly making it harder for you to focus on the key points. To make things clearer and more concise, let me offer a brief and focused summary of the classification of coatings one final time.

Silicone is primarily applied to fabrics to enhance their tear resistance, water resistance, and elasticity. It can substantially improve the puncture resistance of the fabric. However, a notable disadvantage is that silicone-treated surfaces tend to attract and retain dust easily.

Polyurethane primarily improves the fabric’s hydrostatic pressure(MM). It is typically applied to one side of the fabric in a manner similar to solid adhesive. Once the adhesive cures, it forms a polyurethane (PU) layer that endows the fabric with effective waterproof and rainproof properties. However, a notable disadvantage is that polyurethane compromise the fabric’s tear resistance. And TPU ? There is a link to explain it.