TPU fabric is an airtight and waterproof material. Unlike the cheaper PVC, TPU does not contain excessive polluting substances such as heavy metals in its composition and is highly environmentally friendly. Therefore, TPU fabric is often used in medical equipment such as oxygen bags, medical mattresses, and inflatable pillows and so on. It costs higher than PVC ,EVA , TPE and so on, So we usually just can see it used on high-end products.

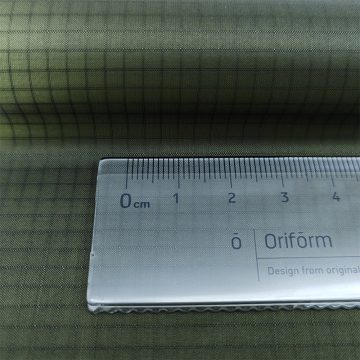

Then how does it manufactured ? Different from normal coating like pu , silicone glue. TPU is make the material from TPU granule and melted to a little glue. The formation process of TPU-coated fabric resembles the generation of molten lava. Initially, the particles are heated to a specific temperature, transforming them into a semi-liquid state similar to volcanic lava. Subsequently, this semi-liquid TPU is applied onto the fabric surface. Under controlled air pressure, the TPU adheres firmly to the fabric. The applied pressure causes a small amount of TPU to penetrate the gaps between the yarns, without fully permeating through the fabric. As a result, the pores of the fabric are effectively sealed, leading to superior airtightness and water resistance. It is important to note that due to the pressure applied during processing and the inherent plasticity of TPU, the tear resistance of the final coated fabric is significantly compromised. The material becomes brittle, similar to paper, which reduces its overall tear strength. Tensile Strength is still good and same to fabric just dyed.

Please rest assured that after high-frequency welding is applied to TPU, the resulting fabric strength is sufficient for normal product usage, provided that sharp objects are not used to deliberately damage the material. Alternatively, selecting a thicker and more durable base fabric can further ensure that the strength requirements of the final product are met. Suitable base fabrics include ultra-high-strength nylon 66, industrial polyester filament, or 420D/500D Cordura. Even with the slight strength reduction that may occur during TPU application, the overall fabric strength remains high. These types of fabrics are typically thick and robust, making them ideal for applications such as inflatable boats, life jackets, life buoys, and large inflatable vessels.

In addition, TPU materials can be classified into polyurethane-based and polyether-based types, which generally exhibit distinct characteristics. The polyurethane-based TPU has relatively low formulation viscosity during production. It tends to hydrolyze more rapidly upon prolonged exposure to water, potentially reducing the service life of the final product. Polyurethane-based TPU is commonly used in outdoor inflatable products such as camping pads, balloons, and oxygen bags. In contrast, polyether-based TPU has higher formulation viscosity, making it more suitable for water-related applications such as packrafts and boats. Generally, fabrics made from polyether-based TPU are more expensive than those made from polyurethane-based TPU.